Cov khoom

-

Yas Txiv Hmab Txiv Ntoo Zaub Cia Crate Txhaj Pwm

Cov khoom tseem ceeb ntawm cov khoom siv pob tawb yog cov khoom siv PE, los ntawm kev txhaj tshuaj molding txheej txheem kev sib xyaw cov khoom yas, lub zuag qhia tag nrho ruaj khov, muaj zog tenacity, pov tsis yooj yim rau kev puas tsuaj, yog dav siv, feem ntau nyob rau hauv tag nrho cov kev mus los ntawm lub neej turnover, ntim. kev tiv thaiv kev puas tsuaj, khaws cia thiab khaws cia, kev faib cov kab ntau lawm thiab lwm yam.Yas turnover box series pwm (xws li yas npias thawv pwm, yas dej tank pwm, yas txiv hmab txiv ntoo lub thawv pwm, ntim lub thawv pwm, xov lub thawv pwm, yas thawv pwm, kaw lub thawv pwm, hnab looj tes pwm, cia thawv pwm, thiab lwm yam) feem ntau siv pwm steel: 45 #, 40 Cr, P20,2738,2316,718, NAK 80, S136 thiab lwm yam.

-

High Precision Txhaj Moulding Yas Qhov Chaw PP PE Khw Muag Khoom Pwm

Yas pob tawb pwm yog cov pwm hauv tsev ntau heev, siv dav heev, pwm siv cov tshuab dhos ua haujlwm ceev, siab precision, lub neej ntev, ua lub pob tawb tuaj yeem siv rau hauv kev ua liaj ua teb, kev lag luam, tsev neeg, pob tawb yas muaj ntau heev hauv lub neej txhua hnub, xws li ntxuav cov pob tawb, pob tawb qias neeg, pob tawb yuav khoom thiab lwm yam muaj cov khoom siv yas, txhua yam yog cov pob tawb yas.Peb tuaj yeem pom qhov universality ntawm daim ntawv thov pob tawb yas.

Feem ntau siv cov pob tawb yas loj muaj 1L / 1.5L / 2L / 3L / 5L / 6L, Leiao lub tuam txhab ua cov pob tawb yas pwm tau dhau los ua neeg nyiam nrog kev lag luam, kom deb li deb tau ua ntau txhiab khub yas pob tawb pwm, los ntawm peb lub tuam txhab. pwm tsim cov txheej txheem, tsis tsuas yog tuaj yeem txhim kho lub neej ntawm cov pwm, tab sis kuj tuaj yeem ua rau cov pob tawb yas pwm txhaj tshuaj nto gloss ntawm cov khoom, tib lub sijhawm yuav tsis tshwm sim ya / ntaub plaub.Peb lub tuam txhab kuj tseem maj mam sau los ntawm qhov pib ntawm kev ua tsis tiav ntawm cov kev paub dhau los, thiab niaj hnub ua tus tswv ntawm cov yas pwm tsim tshuab. -

Yas Txhaj Pwm Tsav Tsheb Tsav Tsheb Pwm Tsav Tsheb Tsav Tsheb Fender Pwm

Cov av nkos phaj yog lub phaj qauv ntsia tom qab lub thav duab sab nrauv ntawm lub log, feem ntau yog ua los ntawm cov khoom siv roj hmab zoo, tab sis kuj siv cov yas yas.Lub fender feem ntau yog mounted rau ntawm ib tug hlau baffle, cowhide baffle, yas baffle, thiab roj hmab baffle qab lub tsheb kauj vab los yog tsav tsheb log.

-

Yas Txhaj Moulds Goblet Transparent PC Caw iav Mould iav khob pwm Champagne iav Pwm Liab Caw iav Mould

Pwm yam ntxwv: yas khob pwm txias: siv dej circulating, zoo txhim kho cov khoom zoo thiab pwm efficiency.

Medium-theem kev kho mob ntawm lub khob yas pwm: kho kom zoo thiab txhim kho hardness.

Tom qab kev kho mob ntawm lub khob yas pwm tom qab kev kho mob: tom qab kev kho mob: kev kho nitride, yas pwm nto hardness yog ntau dua HV 850, quenching kev kho mob, tag nrho hardness ntawm pwm kab noj hniav tuaj yeem ncav cuag HRC 48 degrees. -

Yas Txiv neej Threaded 90 Degrees Dej Yeeb Yeeb Fitting Molding PVC Luj Tshib Txhaj Pwm

Raws li kev ua haujlwm ntawm cov yeeb nkab fittings, peb tuaj yeem faib cov yeeb nkab fittings pwm rau hauv hom hauv qab no

1. PVC yeeb nkab haum tuag (rau kev kub siab thiab tsis tshua muaj siab xws li cov dej thiab cov kua dej)

1) CPVC yeeb nkab haum pwm yog siv rau qhov chaw siab

2) UPVC yeeb nkab haum pwm yog siv rau cov kua dej

3) PVC chaw nres nkoj expansion yeeb nkab haum pwm (tub ntxhais extraction system rau dej muab)

4) Hlau yeeb nkab fittings pwm, txhua yam ntawm PVC yeeb nkab fittings embedded rau hauv phab ntsa.

2. PPR haum pwm (rau cov dej hauv tsev, dej txias thiab kub)

3. PP yeeb nkab haum pwm

1) PP lossis PPH expansion yeeb nkab haum tuag nrog cov txheej txheem rho tawm

2) PP dej yeeb nkab pwm

3) PPH chav dej pwm siv rau chav dej.

4. Tsis tas li ntawd, cov yeeb nkab tshwj xeeb fittings yog ua los ntawm ABS, PA + GF thiab PPSU khoom

Raws li cov kws tshaj lij yeeb nkab fittings pwm chaw tsim tshuaj paus, peb txaus siab rau kev tsim kho pwm pwm. -

Yas Pwm rau Cov Khaub Ncaws Pwm, Yas Pwm rau diav rawg thiab riam, diav thiab diav rawg pwm, Crystal Fork Pwm

Cov khoom siv yas ntawm riam thiab rab diav rawg feem ntau muaj PP PS ob yam.Cov ntaub ntawv yas sib txawv, kev xaiv cov khoom siv hlau ntawm cov pwm kuj txawv.Cov khoom siv hlau ntawm riam, diav rawg thiab diav pwm feem ntau xaiv H13, S136,2344,2316, quenching khoom thiab lwm yam ntaub ntawv hlau.Vim tias cov khoom siv riam, diav rawg thiab rab diav yog cov khoom siv ceev ceev, yog li cov pwm feem ntau qhib rau hauv ntau qhov kab noj hniav, thiab cov pwm tsim los rau hauv ib lub square lossis puag ncig.Yog tias cov pwm tsim los ua square, ces lub semi-kub ntws, cov pwm ua los ntawm kev ntxig.Lub tshuab ua haujlwm ntawm Leo riam, diav rawg thiab diav pwm muaj kev kub ceev zoo carving, kev kub ceev milling thiab lwm yam.Ordinary riam, diav rawg thiab diav pwm feem ntau yog ob lub ntsej muag pwm, thiab folding ntawm rab riam, diav rawg thiab diav pwm, nyob rau hauv lub hauv paus ntawm ob flap pwm ntau swb.Yog li folding riam thiab rab diav pwm yog qhov nyuaj dua li rab riam thiab rab diav pwm.

-

Yas Txhaj Mould rau Ntxuav Tshuab Npog Yas Pib Pwm Lub Tsev Khoom Pwm

Tshwj xeeb hauv kev tsim cov tshuab ntxhua khaub ncaws pwm, muab txhua yam tshuab ntxhua khaub ncaws yas pwm: ob lub tog raj kheej ntxhua khaub ncaws pwm, ib lub tog raj kheej ntxhua khaub ncaws pwm, tshuab ntxhua khaub ncaws tswj pwm, tshuab ntxhua khaub ncaws pwm, tshuab ntxhua khaub ncaws pwm, tshuab ntxhua khaub ncaws tshwj xeeb dej yeeb nkab pwm, tshuab ntxhua khaub ncaws dej twj pwm.Txog tam sim no, peb tau tsim ntau tshaj 20 teeb ntawm 6 kg, 7 kg, 8 kg tshuab ntxhua khaub ncaws pwm.

Rau kev xaiv cov hlau tuag, peb xaiv DIN 1.2311 los tsim lub tshuab ntxhua khaub ncaws;stainless hlau S136;thiab DIN 1.2343. -

Yas Txhaj Pwm rau Kev Ua Liaj Ua Teb Zaub Npias Txiv Hmab Txiv Ntoo Lub raj mis Lub thawv Turnover Box Crate Storage Chaw tsim tshuaj paus

Yas Crate lub thawv yog tsim los ntawm kev txhaj tshuaj molding, ib qho cuab yeej los tsim cov khoom yas thiab ua tiav cov qauv thiab qhov loj me.Txhaj tshuaj molding yog ib txoj hauv kev siv hauv kev tsim khoom loj ntawm qee qhov zoo li tus thiab txoj haujlwm.Tshwj xeeb yog hais txog cov khoom cua sov melting los ntawm kev kub siab rau hauv pwm kab noj hniav, tom qab txias thiab kho, kom tau txais cov khoom tsim.

-

Vaj Puam Siv Tshiab Tsim Rattan Rooj Tog Zaum Yas Rooj Zaum Rooj Txhaj Pwm

Leiao lub tuam txhab yuav tsum feem ntau ua raws li cov hauv paus ntsiab lus hauv qab no thaum xaiv lub rooj zaum yas pwm kev faib tawm nto:

① Kev faib tawm saum npoo yuav tsum raug xaiv ntawm cov qauv ntawm cov khoom yas

② Txiav txim siab qhov zoo pwm tuav hom kom yooj yim rau kev tso tawm ntawm cov khoom yas

③ Saib xyuas qhov tseeb ntawm cov khoom yas

④ Ua tau raws li qhov zoo thiab qhov xav tau ntawm cov khoom yas

⑤ Yooj yim rau kev tsim pwm thiab ua haujlwm

⑥ Nco ntsoov cov txiaj ntsig ntawm kev tsom mus rau thaj tsam subtype

⑦ Kev cuam tshuam ntawm cov nyhuv tso tawm thiab sab core extraction

Hauv qhov tsim tiag tiag, nws tsis tuaj yeem ua tau raws li cov ntsiab lus saum toj no.Feem ntau, peb yuav tsum nkag siab qee qhov kev xav tau tseem ceeb hauv cov txheej txheem kev cai ntawm lub rooj zaum, thiab txiav txim siab qhov kev faib tawm tsim nyog nyob rau hauv qhov chaw no.Yog li, cov qauv ntawm ib khub ntawm lub rooj zaum yas pwm yog qhov tsis tsim nyog pom nws qhov kev faib tawm. -

Tuam Tshoj Durable Tsev Yas Sab nraum zoov Square Rooj Pwm

Pwm yam ntxwv: yas khob pwm txias: siv dej circulating, zoo txhim kho cov khoom zoo thiab pwm efficiency.

Medium-theem kev kho mob ntawm lub khob yas pwm: kho kom zoo thiab txhim kho hardness.

Tom qab kev kho mob ntawm lub khob yas pwm tom qab kev kho mob: tom qab kev kho mob: kev kho nitride, yas pwm nto hardness yog ntau dua HV 850, quenching kev kho mob, tag nrho hardness ntawm pwm kab noj hniav tuaj yeem ncav cuag HRC 48 degrees saum toj no. -

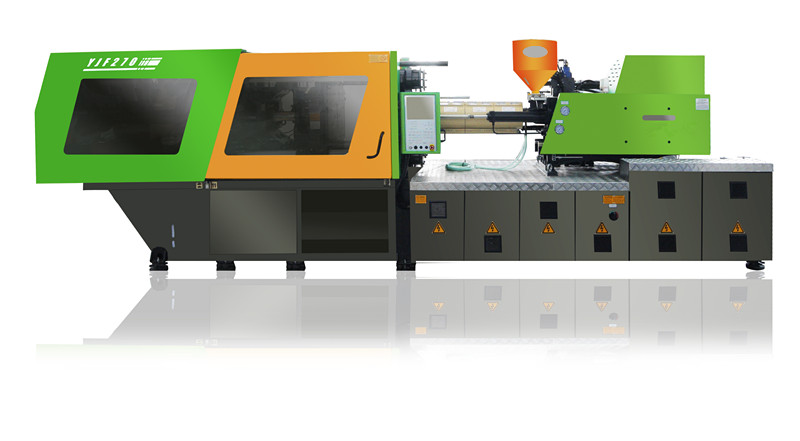

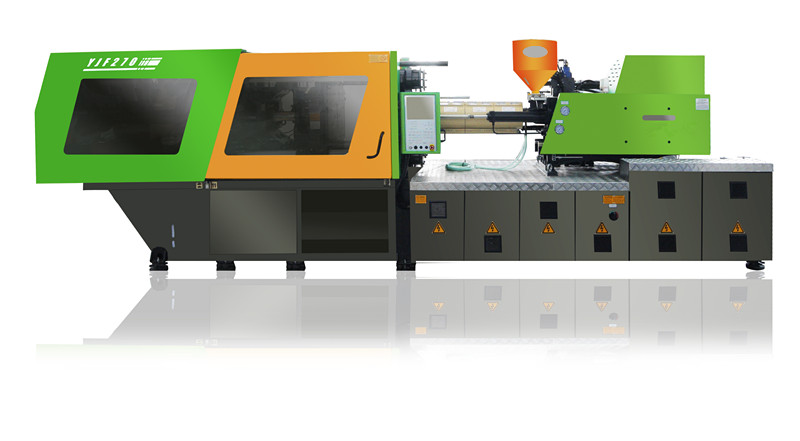

High-Speed Injection Moulding Tshuab

1. Muaj peev xwm txhaj tshuaj muaj zog

Qhov siab tshaj plaws txhaj tshuaj ceev yog 300 hli / s-500mm / s, thiab txhaj tshuaj ceev ceev yog nyob ib ncig ntawm 10 m / s

2. High precision

Lub kaw-voj tswj ntawm txoj hauj lwm thiab lub siab tuaj yeem ua kom qhov tsawg kawg nkaus qhov raug yuam kev ntawm kev txhaj tshuaj thiab ntsuas kev txhaj tshuaj molding tshuab (F series) tuaj yeem paub txog kev ua haujlwm ntawm kev kub siab vs.kev kub ceev thiab kev kub siab vs.High ceev thiab yog tsim rau zus tau tej cov khoom noj txom ncauj, lens, electronic precision khoom, thiab lwm yam

-

Txhaj Moulding Tshuab Rau PET Preforms

1. Ua kom lub ntim ntim, uas yog tsim nyog rau kev tsim khoom ntawm ntau kab noj hniav.Ua raws li cov kev xav tau sib txawv, nws yog qhov zoo dua rau kev tsim cov ntim, sib sib zog nqus kab noj hniav thiab kev kub ceev PET preform khoom.

2. PET tshwj xeeb ntsia hlau signifi cantly tsub kom lub melting ceev thiab txhaj ntim, txo lub plasticizing kub, zoo txhim kho lub shrinkage ntawm lub preform thiab txhim kho lub pob tshab.

3. Ua kom lub zog thimble thiab ejection stroke, uas yog tsim nyog rau kev sib sib zog nqus kab noj hniav PET preform molding.